YUFA has always adhered to the connection of “Science and technology as the guide, quality for survival, and reputation for development”, focusing on exchanges and cooperation with scientific research units and universities. Established long-term cooperative relations with many scientific research units.

Yufa Group has a team of 20 experienced senior product research and development personnel. Among them, two Ph.Ds are primarily focused on refining and researching the technology related to oxide fine ceramics, including powder preparation, molding, and sintering. In addition, there is a dedicated team of 30 diligent quality inspection personnel, nearly 200 skilled production personnel, and 10 specialized after-sales service teams. These teams work tirelessly around the clock to provide heartfelt customer service.

Yufa Group’s products are distributed to over 40 countries and regions, including but not limited to the United States, Germany, South Korea, Japan, Turkey, Pakistan, and India, through a combination of online and offline marketing strategies.

A research and development system with various alumina characteristics is established, comprising a chemical analysis room, a physical performance testing room, a process laboratory, and an application laboratory. This system is equipped with comprehensive equipment and methods.

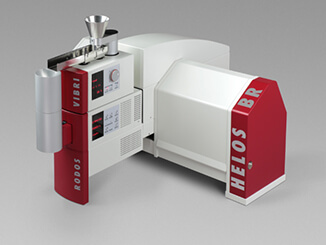

Germany Sinpatec Laser Particle Sizer

High-speed specific surface and aperture analyzer

Japan Electronic Scanning Electron Microscope

Chemical Analyse, Testing

Japan Electronic Scanning Electron Microscope

Chemical Analyse, Testing

YUFA always emphasizes the importance of passing the quality inspection before selling any products. YUFA possesses its own dedicated quality inspection laboratory and personnel. Throughout the production process, starting from the raw materials entering the factory to the final finished products leaving the factory, YUFA conducts inspections based on different dosages and in accordance with the company’s matching inspection standards. The number of inspections conducted ranges from a minimum of 10 times to potentially exceeding 40 inspections.

After being produced, products should undergo inspection based on established standards. If all items meet the technical requirements, they are considered qualified. In order to ensure quality supervision and inspection, the inspected products are categorized into various particle size ranges. A random selection of a particle size is made for sampling purposes.

| Batch, t | Sample Number |

| < 0.5 | 6 |

| > 0.5-1 | 8 |

| > 1-3 | 12 |

| > 3-10 | 20 |

| > 10-20 | 40 |

| Note: when batch is more than 20 tons, the sampling is carried out by batch. | |

YUFA has always maintained a strong commitment to the integration of “Science and technology as the compass, quality for sustainability, and reputation for progress”. The organization primarily emphasizes collaborations and partnerships with scientific research units and universities. It has successfully established enduring cooperative relationships with numerous scientific research entities.

China Abrasives and Grinding Research Institute

Luoyang Refractory Research Institute of Sinosteel

School of Materials Engineering, Henan University of Technology

Shanghai Baosteel Research Institute

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Xinxiang University