Aluminium oxide can exist in one of several crystalline forms, including the most stable one – alpha-aluminium oxide.

α-Al2O3 modification occurs in nature as corundum. Normal corundum is a non-transparent fine- or coarse-grained mineral, colourless or greyish; sometimes it may look like a large non-transparent crystal. Large transparent corundum crystals are precious stones. Alpha-modification crystals can also be red (ruby), blue (sapphire), violet or of other colours due to the admixtures of oxides of different metals.

The Properties and Production of α-Aluminium Oxide

Aluminium oxide can occur as separate or grouped crystals, grains, isolated impregnations or compacted granular aggregates. Corundum has a shine ranging from metallic to matted one. In some cases, the asterism effect is observed due to inclusions of fine oriented rutile crystalloids.

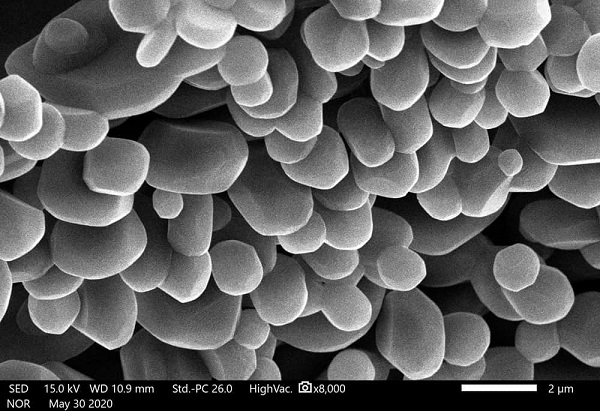

Alpha-aluminium oxide is shaped as insoluble crystals, having a melting temperature of 2050°C, a density of 3,960 kg/m3 and a boiling temperature above 3,000°C. The material is resistant to chemical attacks and acid-insoluble.

The artificial alpha-form of aluminium oxide is obtained from bauxites and other high-alumina minerals using a thermal treatment method. Commercial alpha-aluminium oxide can be produced by heating aluminium hydroxide and its salts to above 900°C. When aluminium salts are heated to temperatures above 600°C, a cubic gamma-aluminium oxide appears, which irreversibly transforms into alpha modification after reaching 900°C.

Application of Alpha-Aluminium Oxide

For industrial purposes, α-aluminium oxide, which has a high melting temperature, is used for producing refractory goods, electric insulation products, electroceramics, radio ceramics and other special types of ceramics, as well as electrical porcelain and various enamels. Alumina oxide ceramics are characterized by increased hardness, fire resistance, insulation and antifriction properties, which permit use for integrated-circuit substrates, gas-discharge lamp burners and valve gates.

Due to high hardness, artificial alpha-aluminium oxide can be used in the production of abrasive and polishing materials and cutting disks of polishing and cutting tools. The material of this modification is also a raw material for the commercial production of aluminium and acts as a catalyst, adsorbent and inert filler in the chemical industry.

Microtech uses its own technologies for obtaining various modifications of aluminium oxide. State-of-the-art production capacities permit our enterprise to produce aluminium oxide-based products, which fully comply with our customers’ requirements in terms of their performance.